Science, Research and Development

- Sputtering: PVD, HiPIMS, CVD;

- Chemical treatments: Electropolishing, etching, deposition, plasma treatments, cleaning;

- Materials, Surface analysis.

Electrolytic deburring is an electrochemical process that allows the polishing of any metal surface even in areas where manual methods or mechanical processing are impractical or not suitable for quality, productivity or economic reasons.

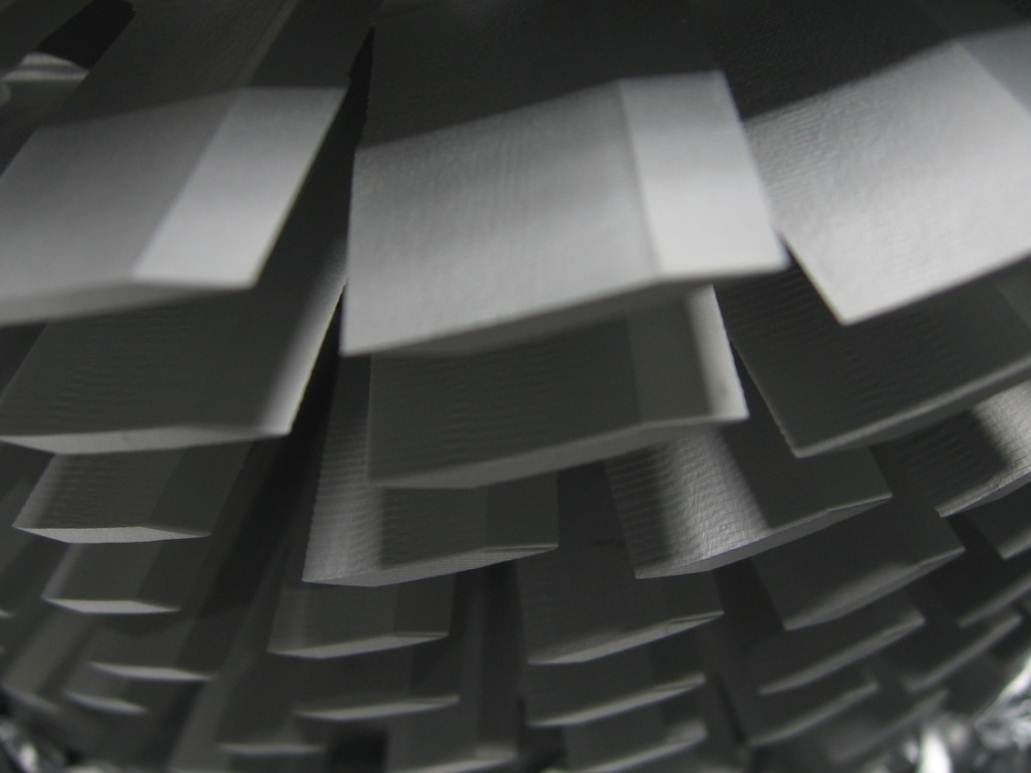

Rotary blades of vacuum pump

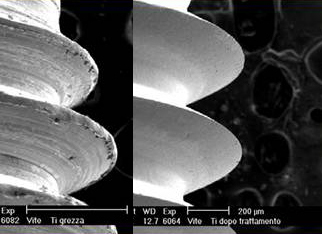

Electrochemical deburring of a titanium dental implant pin

When it is not possible to connect the part to be treated as an electrode, it is possible to perform chemical deburring by simply inserting the part in an aggressive chemical solution specific for the metal to be treated. Compared to electrochemical deburring it has the advantage of being cheaper and easier to use, especially for small parts, but it is slower.

Some applications of this technique in various fields are:

- Copper zips

- Turbo molecular pump rotors

- Titanium Dental Pins

- Gold jewellery without the use of cyanides