Science, Research and Development

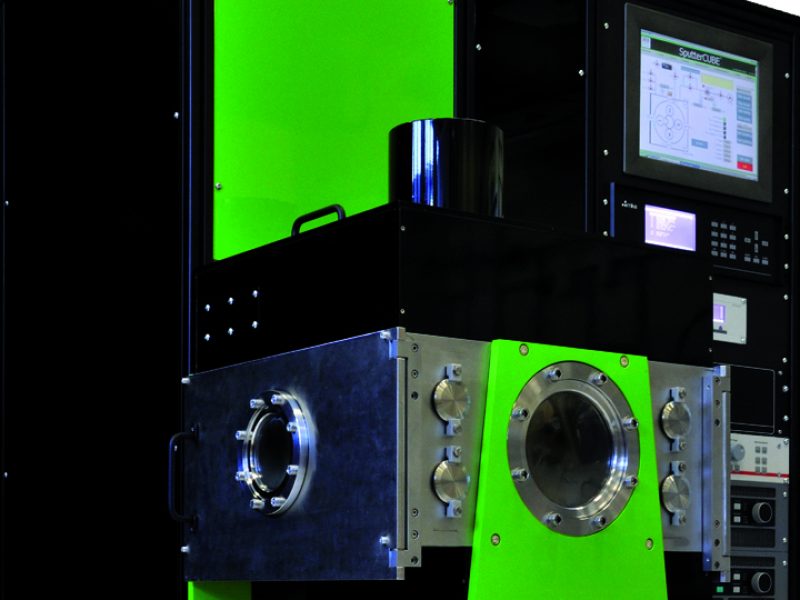

- Sputtering: PVD, HiPIMS, CVD;

- Chemical treatments: Electropolishing, etching, deposition, plasma treatments, cleaning;

- Materials, Surface analysis.

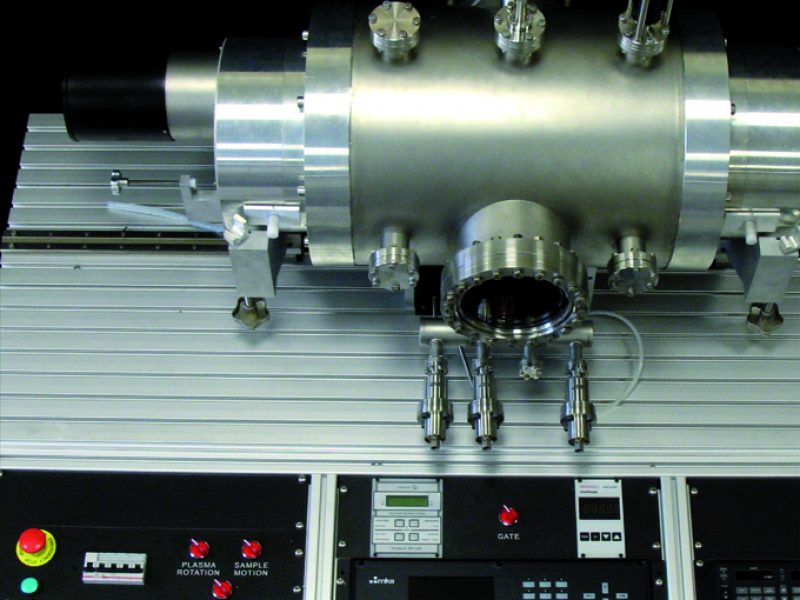

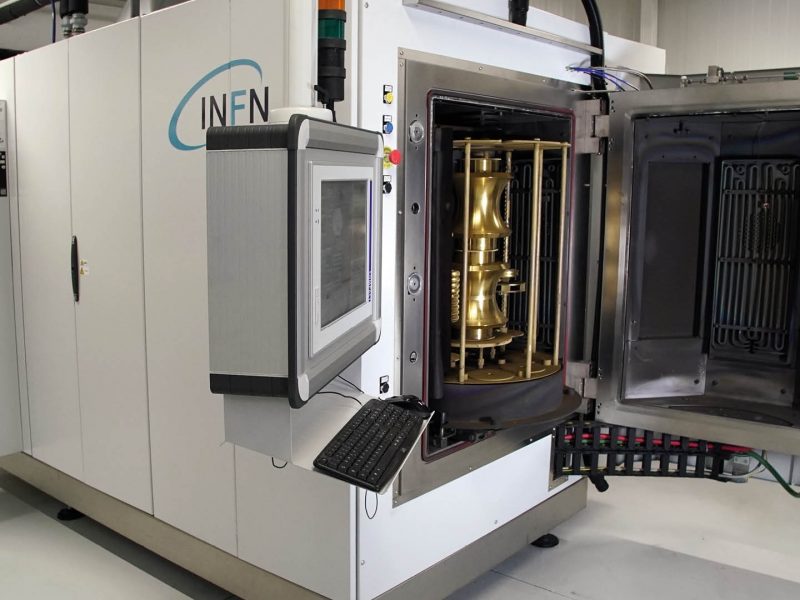

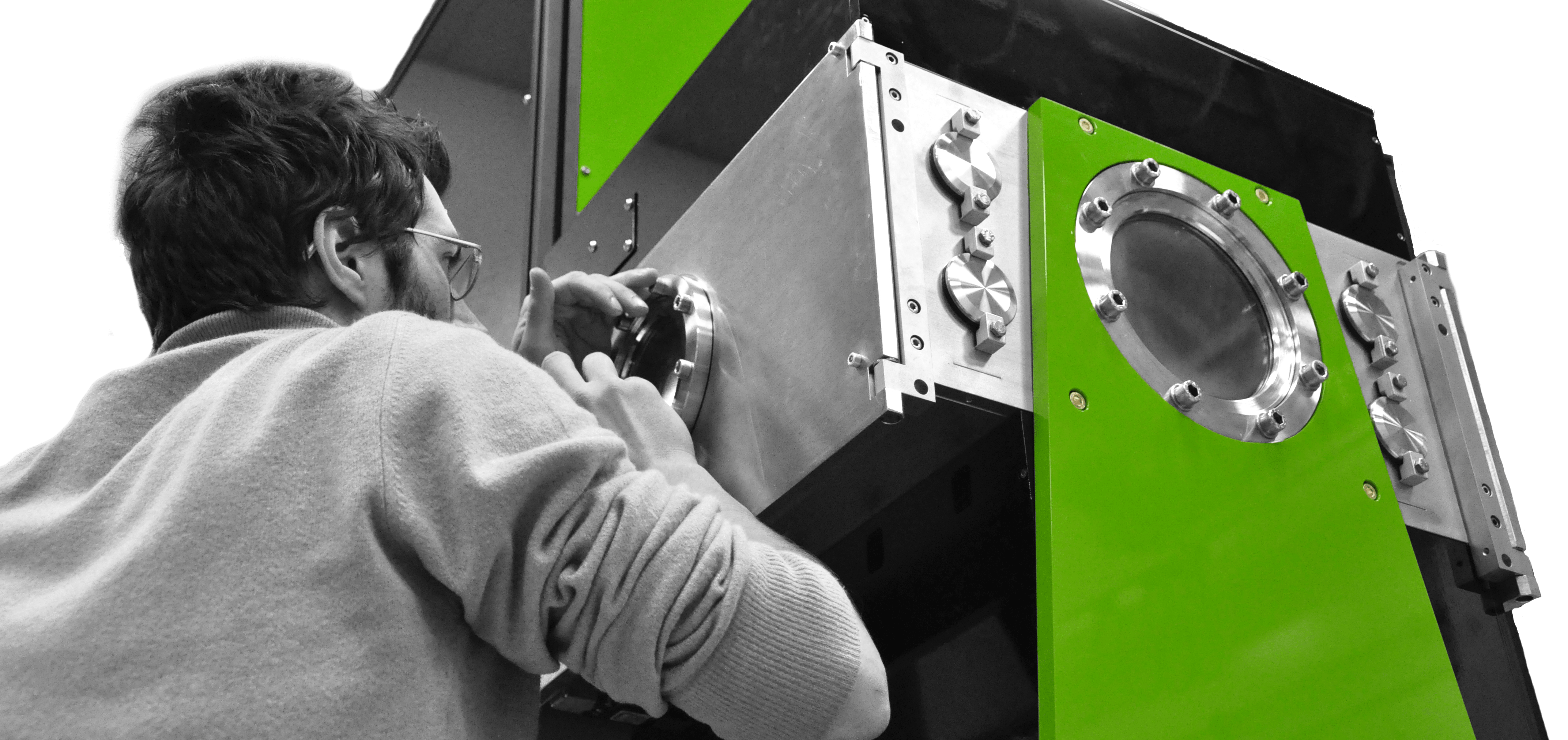

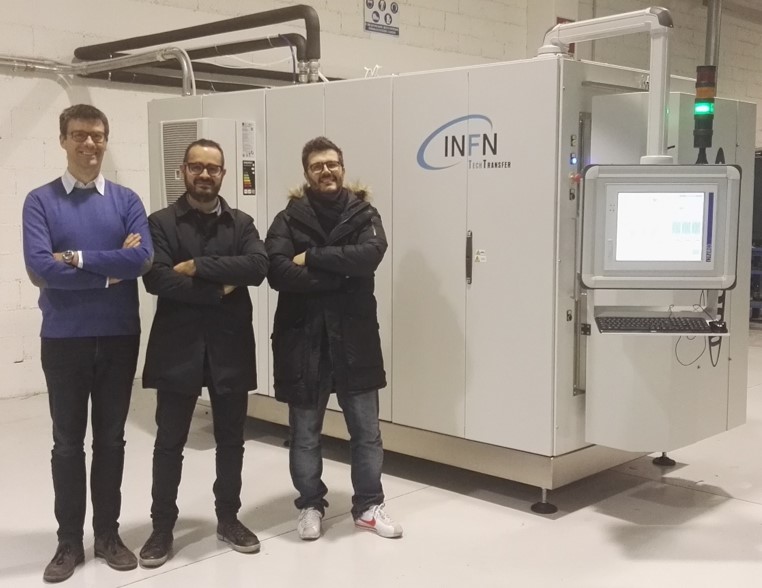

Sputtering is a PVD technique (Physical Vapor Deposition), a low temperature process where a plasma is generated in vacuum, in order to bombard the target connected to the negative electrode of an electric power supply with positive ions. The target is vaporized and the vapors are deposited on the substrate creating a thin atomic layer on an atomic layer. That allows the deposition of thin films of any material on a substrate of a second material, with practically infinite applications ranging from high temperature superconducting films to hard coatings for cutting tools, from films that limit the secondary ionization of the surfaces to the materials used in thermodynamic panels.

This technique is used for making films:

- Protective: such as a protective coating capable of resisting corrosion from liquid metal: the thin film developed is capable of reducing the wettability of the corrosive liquid on the surface to be protected.

- Decorative: for example, 24-karat gold films can be made of precious materials on less noble materials such as plastic, wood, mother-of-pearl and fabrics (leathers and furs).

- Functional: The tools used for cutting hard materials and solar panels.

It is a very versatile technique but difficult to standardize, so it is necessary to create a system tailored to the required application, able to optimize the process and the result to the maximum.

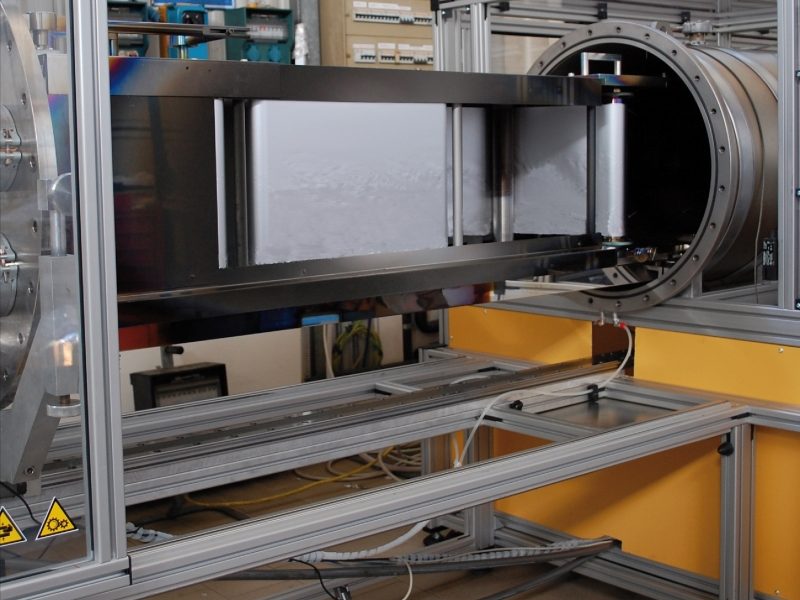

If it is necessary to cover large surfaces with thin films or flexible substrates in large quantities, the PVD technique can be used in a semi-continuous process (called Roll to Roll) by depositing on rolls even hundreds of meters in systems that are called web coatings capable of depositing thin films on aluminum rolls (domopack type) used in the solar thermal industry.

Metallized plastic meshes have also been developed, used in the cellular and smartphone industry, which act both as a faraday cage and as protection for audio speakers.