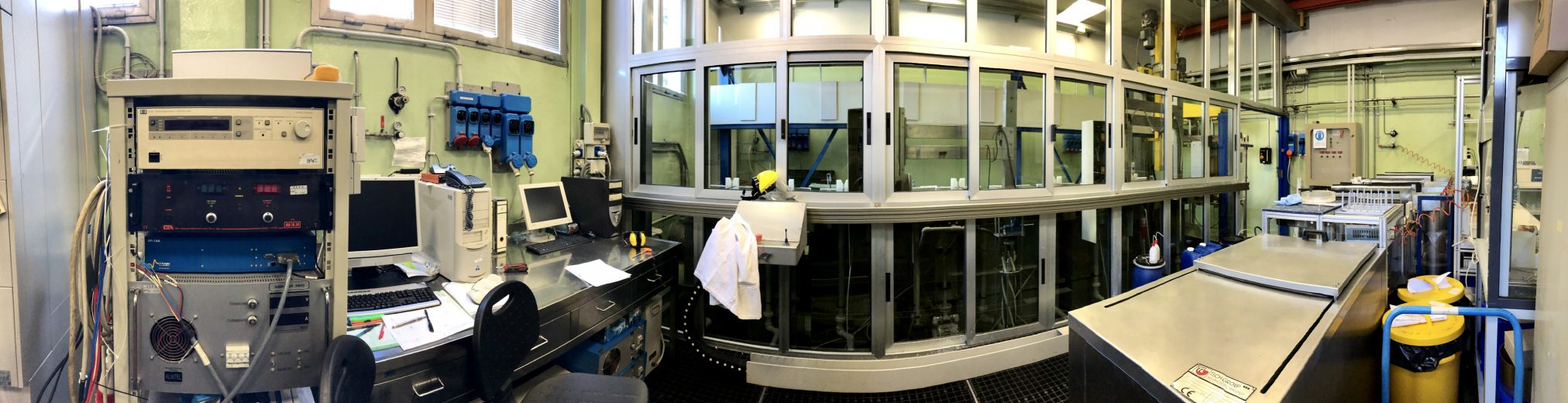

Chemistry Lab:

Two chemistry laboratories are active in Legnaro. The main activities that can be performed are: preparation of surfaces for UHV systems assembly (ultrasonic degreasing, deoxidation, drying with solvents); surface preparation of components for subsequent braze welding in a high vacuum furnace; chemical and electrochemical polishing of the surface of copper and niobium components (resonant cavities, cryostats, detectors); treatments of low-melting alloys; studies of alternative chemical treatments; supply of ultrapure deionized water, ultra-cleaning of copper components from radioactive contaminants.

Chemical etching facility for QWR:

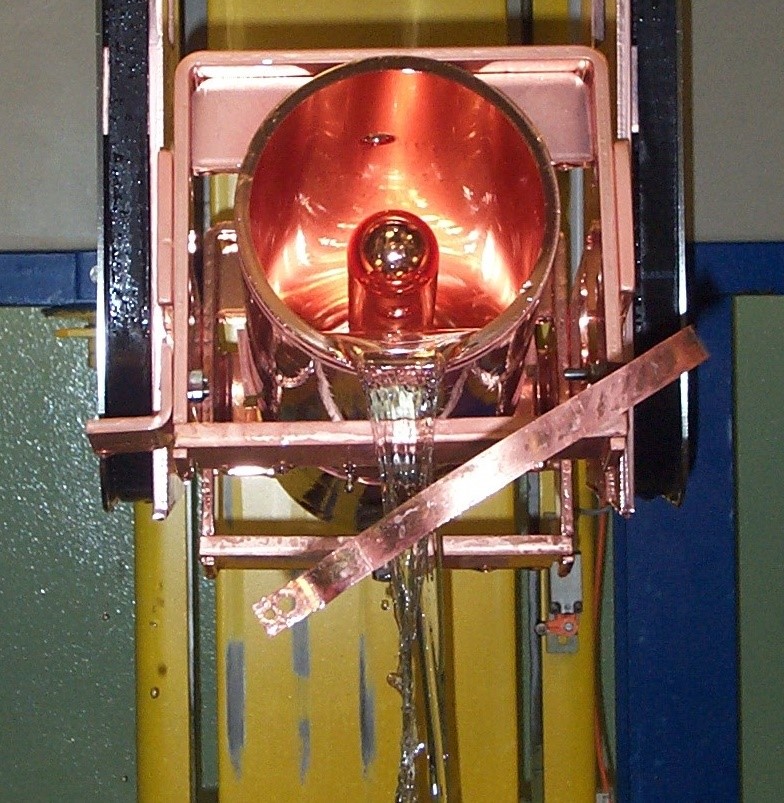

The chemical treatments of the surface of the RF cavity, removing damaged layers and/or possible surface contamination, is fundamental in order to improve cavity performance and mandatory before superconductive coating with thin film. The LNL chemistry laboratory is equipped with a semi-automatic facility, to perform different processes as washing, degreasing, chemical and electrochemical treatments and passivation, necessary for the surface finishing of QWR before the thin film coating.

Fig.1 Semi-automatic chemical plant for QWR treatments

Fig.2 QWR during chemical treatments

Fig3. Electropolishing of elliptical cavity

Additional facilities available are: Chemical hood, semi-automatic plant for chemical treatments of small components, surface treatments of Copper and Niobium 6 GHz cavities (for fast and repeatable R&D). This facility includes moreover, surface machining, electro polishing, chemical etching of Nb and Cu 6 GHz resonators.