Science, Research and Development

- Sputtering: PVD, HiPIMS, CVD;

- Chemical treatments: Electropolishing, etching, deposition, plasma treatments, cleaning;

- Materials, Surface analysis.

Tumbling (also known as barreling) is a process for smoothening of rough surfaces, that took the same natural principle that produces sea glass. Usually, it is maintained in a wet (less often dry) conditions with a presence of abrasive media (such as alumina or embedded ceramics). Inside the SRF community, centrifugal barrel polishing (CBP) is known as a conventional way to polish 9-cell superconductive cavities. At the service, we have a rotary tumbling, that copy planetary movement trajectory.

Tumbling has a list of advantages:

- The relative simplicity of the technique;

- Possibility of automatization;

- High level of reproducibility;

- Possible medium and fine polishing.

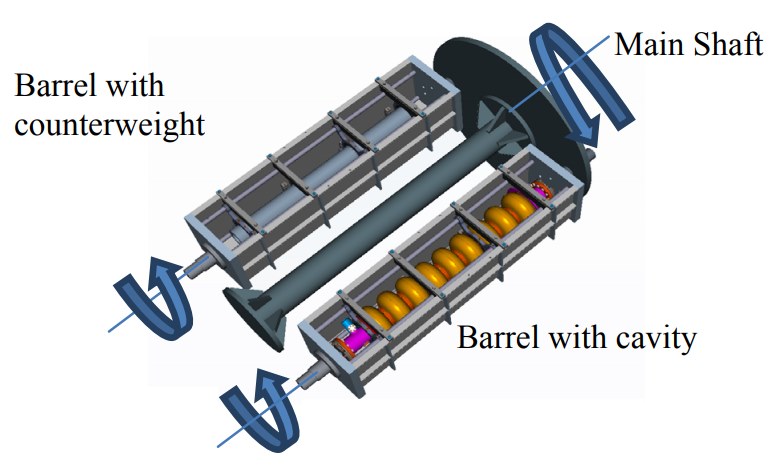

Centrifugal Barrel Polishing [1]

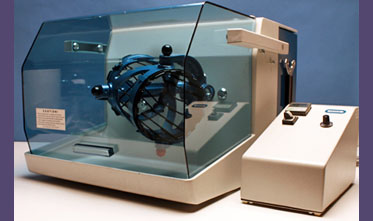

Big Tumbling Machine TURBULA® mixer

Small TURBULA® mixer

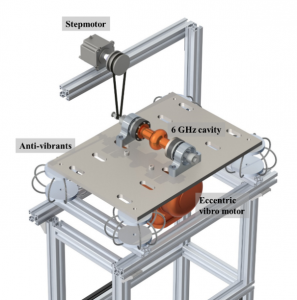

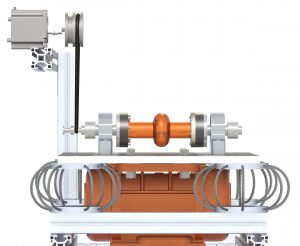

Vibro-Tumbling technique is a combination of vibratory finishing and tumbling technologies that was developed and being used at our service. Initially built and proposed by Yu Goulong in 2013 at INFN-LNL [2] VT technique showed promising results on the 6 GHz cavities. In 2019, when it was proposed to restart research activity on that technique. The idea of the VT is the combination of the vibrational energy with continuous rotation. Internally placed abrasive plays a significant role in surface preparation. Random movements of the abrasive media attacks/scratch the surface in the presence of the liquid media. The complexity of the process is that the internal volume of an elliptical cavity is always limited, and so the media is always the same. In this difficult situation, after a number of research tests, it was achieved 2 g/h (for 6 GHz cavity – 23 um/h) removal rate. VT is able to overperform conventional tumbling cutting speed by an order of magnitude. At the same time, it was developed fine vibratory polishing – achieving a reflective surface with an organic abrasive media or with colloidal system.

Benefits of Vibro-Tumbling over tumbling and CBP:

- Better cutting performance.

- Easily scaling technique.

- Low quantity-media environment.

References:

[1] C. Cooper et al., “Centrifugal Barrel Polishing (CBP) of SRF Cavities Worldwide” in Proc. SRF’11, Chicago, IL USA Jun. 2011, pp. 571.

[2] Yu Guolong, Development of a new mechanical surface treatment for the internal finishing of 6 GHz superconducting cavities, PhD thesis, (2013).

[3] E. Chyhyrynets et al., “Vibro-tumbling as an Alternative to Standard Mechanical Polishing Techniques for SRF Cavities”, in Proc. SRF’19, Dresden, Germany, Jun.-Jul. 2019, pp. 464-466. doi:10.18429/JACoW-SRF2019-TUP026